How Ecotile supports your Cleanroom and ESD requirements

March 17, 2016A cleanroom is a controlled environment where products are manufactured. It is a room in which the concentration of airborne particles is controlled to specified limits.

Ecotile’s MD, James Gedye, explains the proposed ISO Standards for Cleanrooms and how Ecotile’s Industrial and ESD Flooring can provide your organisations’ with a simple and reliable solution that fully supports your Cleanroom requirements.

Eliminating sub-micron airborne contamination is really a process of control. These contaminants are generated by people, process, facilities and equipment and must be continually removed from the air. The level to which these particles need to be removed depends greatly upon the standards required for each organisation.

Cleanroom Floors; the main source of contamination

The bulk of the contamination in any Cleanroom resides on the floor. Therefore it is important that consideration be given to the best flooring solution for your application, as the only way to control contamination is to control the total environment.

Air flow rates and direction, pressurization, temperature, humidity and specialized filtration all need to be tightly controlled. And the sources of these particles need to controlled or eliminated whenever possible. But there is much more to a Cleanroom than air filters.

Cleanrooms are planned and manufactured using strict protocol and methods. They are frequently found in electronics, pharmaceutical, biopharmaceutical, medical device industries and other critical manufacturing environments.

Ecotile’s suitability for use in a Cleanroom / ESD Environment

In order to provide our customers with peace of mind, we measure and report the conductivity of each production batch. As a result of this quality control procedure, we establish a measurement report showing the distribution of conductivity values within a single batch.

These reports are available to the customer upon request.

ISO standards and cGMP regulations for air purity require you to comply by presenting consistent results that can be verified on a regular basis. Ideal for cleanrooms and these kinds of environments, EcoTile satisfies the strictest requirements for particle release behaviour, helping to reduce any threat of contamination.

The homogeneous and impervious structure of our interlocking industrial flooring solution makes it simple to clean and helps to minimise dust and dirt. With its dense network of conductive fibres ensures a guarantee for lifetime conductivity.

Performance is permanent and consistent, independent from air humidity or temperature conditions.

In conjunction with appropriate ESD footwear, EcoTile is fully compliant with the personnel grounding requirements specified in the IEC 61340-5-1 and ANSI/ESD S20.20 standards for ESD Protected Areas (EPA):

Recommendations for ensuring best performance within a Cleanroom environment

Because of the homogeneous and impervious structure of EcoTile the tiles are ideally suited for a clean room environment, however to ensure the best possible results it is essential that the floor is cleaned and maintained in accordance with our recommended cleaning and maintenance guidelines.

The application of a floor sealer (either our standard floor sealer or the ESD floor sealer for ESD protected areas) will further enhance the performance, ease maintenance and extend the life of the flooring.

Proposed ISO Standard for Cleanrooms

Because of the large number of cleanroom standards produced by individual countries it is very desirable that one world-wide standard of cleanroom classification is produced.

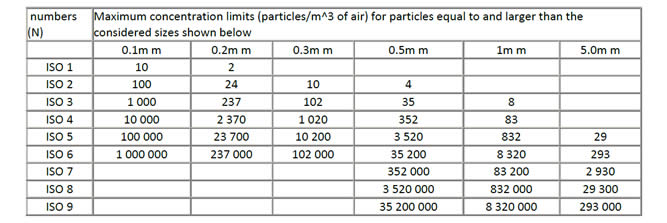

The International Standards Organisation is producing such a document. Because of the number of countries involved and the problems with translation it may be over a year before it is published. However, it is unlikely that it will be different from the table below:

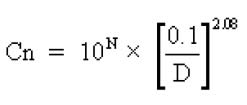

This table is derived from the following formula:

Cn represents the maximum permitted concentration (in particles/m^3 of air ) of airborne particles that are equal to or larger than the considered particle size. Cn is rounded to the nearest whole number.

Table 5 shows a crossover to the old FS 209 classes e.g. ISO 5 is equivalent to the old FS 209 Class 100.

If you would like to discuss your Cleanroom requirements with one of our expert industrial flooring contractors, please contact us today on (+44) 01582 788232

David Bryant-Pugh is sales and marketing manager of Ecotile Flooring. A Member of the Chartered Institute of Marketing (MCIM), David divides his time between creating strategy and tactics for the modular flooring business, and meeting customers to better understand their needs and specific marketplace. Operating across multiple industry sectors (every business has a floor, right!) David’s experience ranges from manufacturing to retail, and everything in between.

Prior to Ecotile, David managed the marketing team at Argos for Business. He previously built a wealth of experience in the foodservice and construction industries as marketing lead. You can find David on LinkedIn