Developed over a 2-year period working exclusively with the UK’s Ministry of Defence (MoD), Ecotile has created a new ultra-low resistance, modular electro-static discharge flooring solution for use in explosives processing facilities and areas where static shocks could be lethal.

Ecotile’s new specialist dissipative tile has been designed to meet the MoD’s Conductive Regime – a protocol required in areas where small static charges can cause OME (Ordnance, Munitions and Explosives) with ignition energies of 1mJ and below to ignite.

So that static can be dissipated rapidly and safely, the Conductive Regime requires flooring to have less floor to earth resistance than civilian ESD flooring.

Reviewed and tested by the MoD Defence Ordnance Safety Group (DOSG) in an Ammunition Process Building (APB), Ecotile’s new modular conductive flooring system delivers an average surface resistivity of 26.4KΩ.

Following a thorough technical assessment by a Senior OME Engineer and DOSG Science & Technology Team Leader, the new Ecotile X500-MoD Specification Conductive Floor Tile has been approved as ‘Product Conformant’, meeting the requirements of both DSA 03. OME Part 2 – Chapter 8 and ESTC Standard No.6 Part 1.

Perfect for use across the defence estate

- Explosives processing facilities

- Ammunition Process Buildings

- Use in Explosive Category C & D licenced buildings

Product Specification & Benefits

The Ecotile X500-MoD Specification modular ESD flooring solution provides average surface resistivity of 26.4KΩ, with a resistance to ground of 1.8 to 9.9kΩ. A slip rating of R10 helps keep personnel safer from slips, and a fire performance rating of Bfl-S1 ensures a Class 1 Spread of Flame rating.

With a 10-year warranty, and an expected service life of 25 years+, the DOSG highlighted in their technical assessment document that modular floors also offer some significant advantages when compared to other currently approved MoD ESD surfaces:

- Currently, when sections of approved flooring are damaged or fall outside of tolerance, large sections of floor must be replaced, or the entire floor

- Replacing large sections of floors is a costly and disruptive event

- Modular floors offer the ability to interchange one damaged tile with another in a matter of minutes and return the building or work area to compliance quickly

- Modular ESD tiles minimise disruption or downtime of an MoD asset whilst providing a significant financial saving

Ecotile have a range of solutions suitable for the defence industry and have worked with MoD, millitary contractors, and manufacturers across the defence industry.

To find out more and request pricing please call us on +44 1582 219009 or email [email protected]

Looking for ESD flooring for industry and electronics manufacturers? Find our standard ESD floor tile here.

Or if you have a specialist ESD or conductive flooring need, share your specification requirements or static control program with us and we may be able to help.

Dimensions: 497mm x 497mm +/- 0.3mm

Thickness: 6.46mm +/- 0.3mm

Weight: 8.40kgs/m²

Guarantee: 10 Years

Anticipated Service Life: 25 Years +

Material: PVC (100% Recyclable)

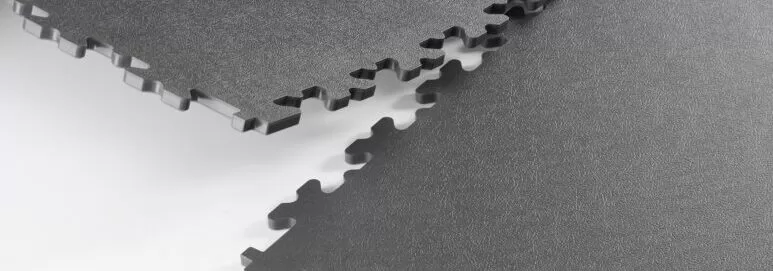

Colors: Dark Grey, Light Grey

Surface Resistivity: Average 26.4KΩ

Resistance to Ground: 1.8 to 9.9KΩ

Walking Test: <100V Static Decay at 15%

Humidity: Static Decay at 15% humidity: 0.01sec

Slip Resistance: EN 14041:2004 DIN 51130:2004 Pass R10

Fire Performance: BS 476: Part 7 DIN 13501: 2007 Class 1 Spread of Flame Bfl-S1 -Does not support combustion

Impact Resistance: EN 13329-549 549kg/cm² Noise Reduction: EN 140-8 >46db

Thermal Insulation: 1.1 m²K/w

Specification

Dimensions: 497mm x 497mm +/- 0.3mm

Thickness: 6.46mm +/- 0.3mm

Weight: 8.40kgs/m²

Guarantee: 10 Years

Anticipated Service Life: 25 Years +

Material: PVC (100% Recyclable)

Colors: Dark Grey, Light Grey

Surface Resistivity: Average 26.4KΩ

Resistance to Ground: 1.8 to 9.9KΩ

Walking Test: <100V Static Decay at 15%

Humidity: Static Decay at 15% humidity: 0.01sec

Slip Resistance: Pass R10

Fire Performance: Bfl-S1 -Does not support combustion

Impact Resistance: EN 13329-549 549kg/cm²

Thermal Insulation: 1.1 m²K/w