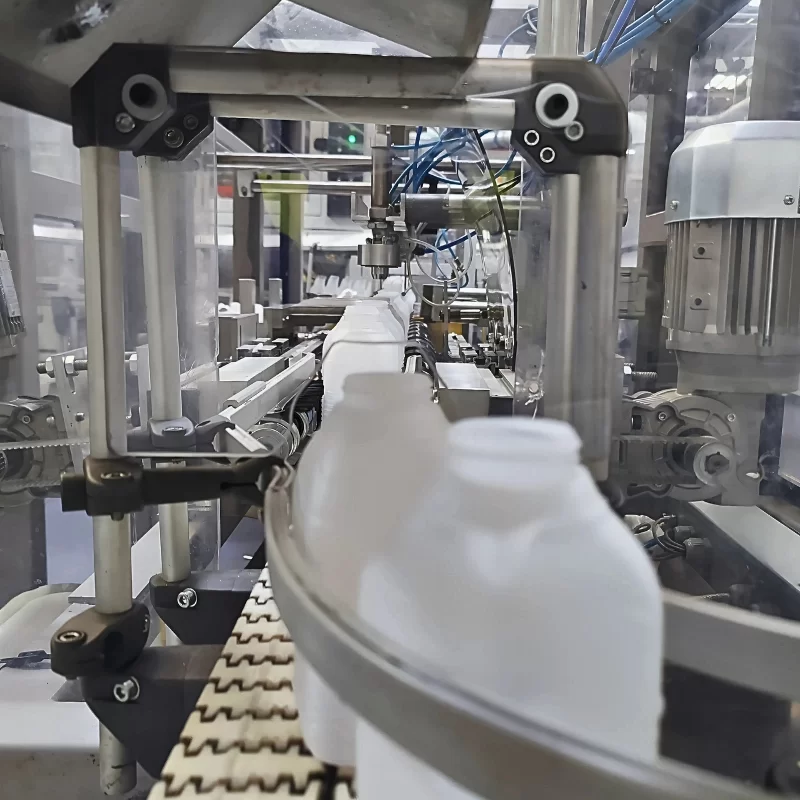

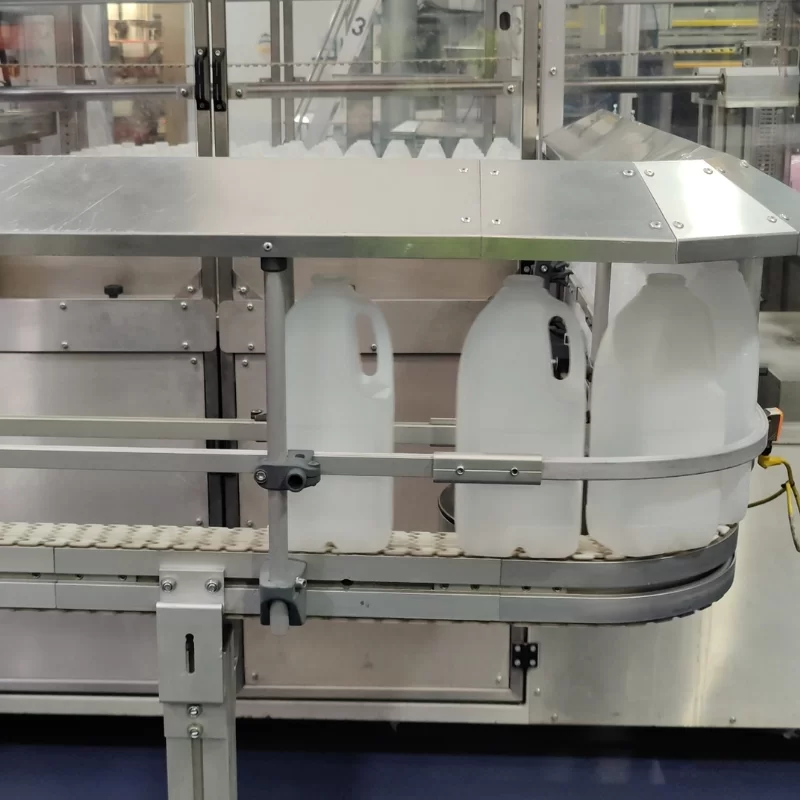

Blowplast Ltd, a successful UK manufacturer of plastic milk bottles, operates two sites with round-the-clock production. As they continued to grow, they faced an unexpected challenge – their flooring. The painted concrete floors were failing under the constant movement of trolleys transporting products from the production line to the warehouse. Every scuff, chip, and crack in the floor coating wasn’t just an aesthetic issue – it was a real operational problem threatening efficiency and hygiene standards.

Their 24/7 production schedule created a significant dilemma. How could they address their flooring issues without shutting down operations? Traditional solutions like epoxy resin required extensive preparation and curing time, which simply wasn’t compatible with their non-stop manufacturing demands. As problems mounted, Blowplast needed a flooring solution that could match their own operational flexibility.

Choosing a durable, no-downtime industrial flooring solution

When Blowplast began evaluating potential flooring options for their 1,800 m² facility across two units in High Wycombe, they had several critical factors in mind:

- The ability to install the flooring without disrupting production

- A solution durable enough to withstand constant trolley traffic

- A low-maintenance surface that would be easy to clean in a food-adjacent manufacturing environment

- Avoiding the long preparation and curing times associated with traditional resin floors

- Ensuring value for money with a long-term solution rather than repeatedly repainting concrete

Before committing to a full installation, Blowplast took a cautious approach by testing Ecotile in their most challenging area. They installed a trial section in the busiest part of the warehouse – an area with constant forklift traffic – and observed its performance over a four-month period.

The benefits of Ecotile’s heavy-duty flooring for factories

- No production downtime during installation

- Eliminated ongoing maintenance issues caused by painted concrete

- Improved the overall appearance of production and warehouse areas

- Enhanced cleaning efficiency with an easy-to-maintain surface

- Withstood intense forklift and trolley traffic without wear and tear

- Provided a cost-effective, long-term solution with the potential for expansion

Seamless industrial flooring installation without disrupting production

We recognised Blowplast’s unique challenges as a 24/7 operation and knew that our interlocking floor tile system would be the ideal solution. Manufactured at our UK facility, our tiles are designed for demanding industrial environments where substrate issues and installation constraints create major challenges.

To ensure a smooth transition, we proposed a phased approach, beginning with a trial installation in the most high-traffic area. This allowed Blowplast to see firsthand how our interlocking system performed under continuous forklift stress before committing to a full installation.

Our technical team worked around their production schedule, installing the tiles in sections to avoid any operational disruption. Because of our interlocking design, we were able to dry-lay the tiles directly over their existing problematic substrate—including oily, damp, uneven, and contaminated areas—without the extensive preparation time required by alternative flooring solutions.

How Ecotile improved safety, maintenance & efficiency

Since switching to Ecotile, Blowplast has complete peace of mind knowing their flooring solution can keep up with the demands of their 24/7 operation. The upgraded floors have created a more professional environment for both employees and visitors, enhancing the overall workplace experience.

Their maintenance team has seen a dramatic reduction in floor-related issues, freeing them up to focus on more critical facility management tasks. The cleaning staff appreciate how easy the new surface is to maintain, which is particularly important in a food-adjacent manufacturing environment.

Production line workers now benefit from a more stable and reliable surface for transporting products, reducing the risk of accidents from damaged flooring. Blowplast’s bottom line has improved through the elimination of constant repainting costs and the prevention of potential production disruptions caused by floor maintenance.

Ecotile's Key Inputs

Long-term success with Ecotile

- Operational continuity – Installation was completed without interrupting their 24/7 production schedule

- Proven durability – A successful 4 month trial in the highest-traffic area confirmed the performance of Ecotile

- Enhanced facility appearance – Professional-looking floors have improved the workplace environment

- Maintenance efficiency – The easy-to-clean surface has reduced ongoing maintenance costs

- Scalable solution – Their positive experience has opened possibilities for expansion to additional areas

- Business-focused approach – A practical solution aligned with the operational realities of continuous manufacturing